Water Spray Extinguishing Systems

“The fact that there has not been a fire in an industrial plant for decades does not prove there is no fire hazard, it only shows that the operators have been lucky – and this luck may run out at any time.” This is cited from a court ruling by the OVG Lüneburg dated 23 September 1976.

Fires cause billions of euros of damage in Germany every year. Production and storage areas where high-calorific substances are handled (e.g. plastics, rubber etc.) are particularly at risk.

Where these products are involved, fires will spread quickly. The speed at which the fire spreads is accelerated significantly by the carrying over of fires and hot spots to other production areas via conveyor belts. In such highrisk areas, T&B water spray extinguishing systems – a combination of fire alarm and water extinguishing system – are used.

Possible Areas of application for Water Spray Extinguishing Systems

Fire Detection

Depending on the local circumstances and the existing fire load, fire detection is usually by means of flame, smoke or heat detectors. Both electric and pneumatic heat detectors can be used. The trigger temperature should be approx. 30°C above the max. ambient temperature in order to avoid false alarms. The maximum area monitored per detector is always determined in accordance with VdS guideline 2095.

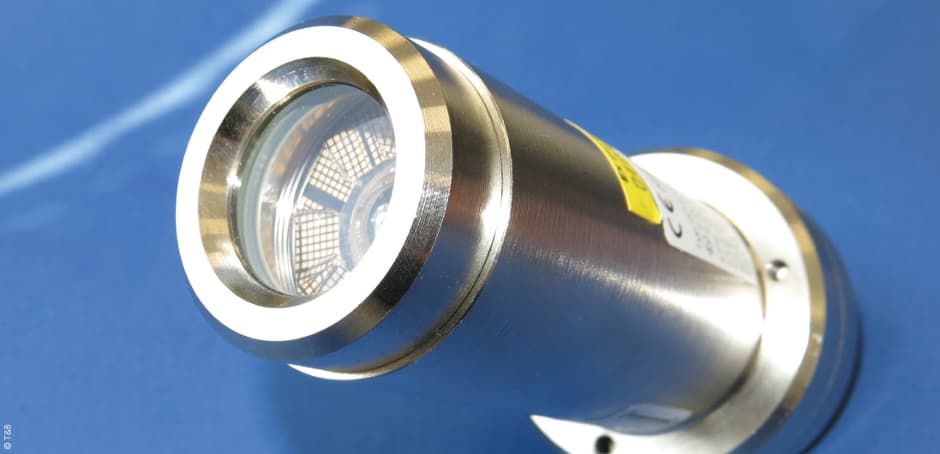

Flame detector for the detection of open flames

Pneumatic triggering elements for triggering following sharp increase in temperature Infrared thermal imaging cameras are used for monitoring larger areas. These localise the location of the fire and actuate the respective water spray extinguishing system

Water Spray Extinguishing Systems

Water spray extinguishing systems in combination with the above-described detection systems detect fires particularly quickly and distribute the water evenly to all the nozzles within an extinguishing area. This quickly cools the burning material and draws the heat from the ambient air. Thus fires can be fought quickly and safely even in critical areas, and the fire is prevented from spreading.

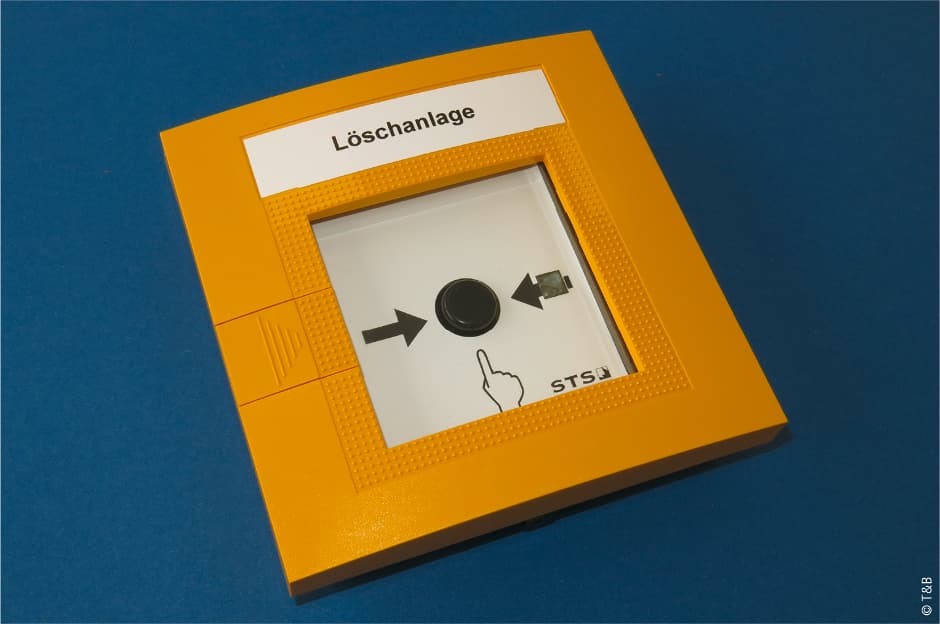

In addition, a water spray extinguishing system can always be actuated manually.

Manual call point for manual actuation of the water spray system

Water spray extinguishing systems with electric actuation can be closed early to quickly end the flow of water after extinguishing has been completed.

The extinguishing water rate is adapted to the respective object to be protected in accordance with the VdS guideline VdS 2109. There is a series of extinguishing nozzles available for a wide range of different application cases:

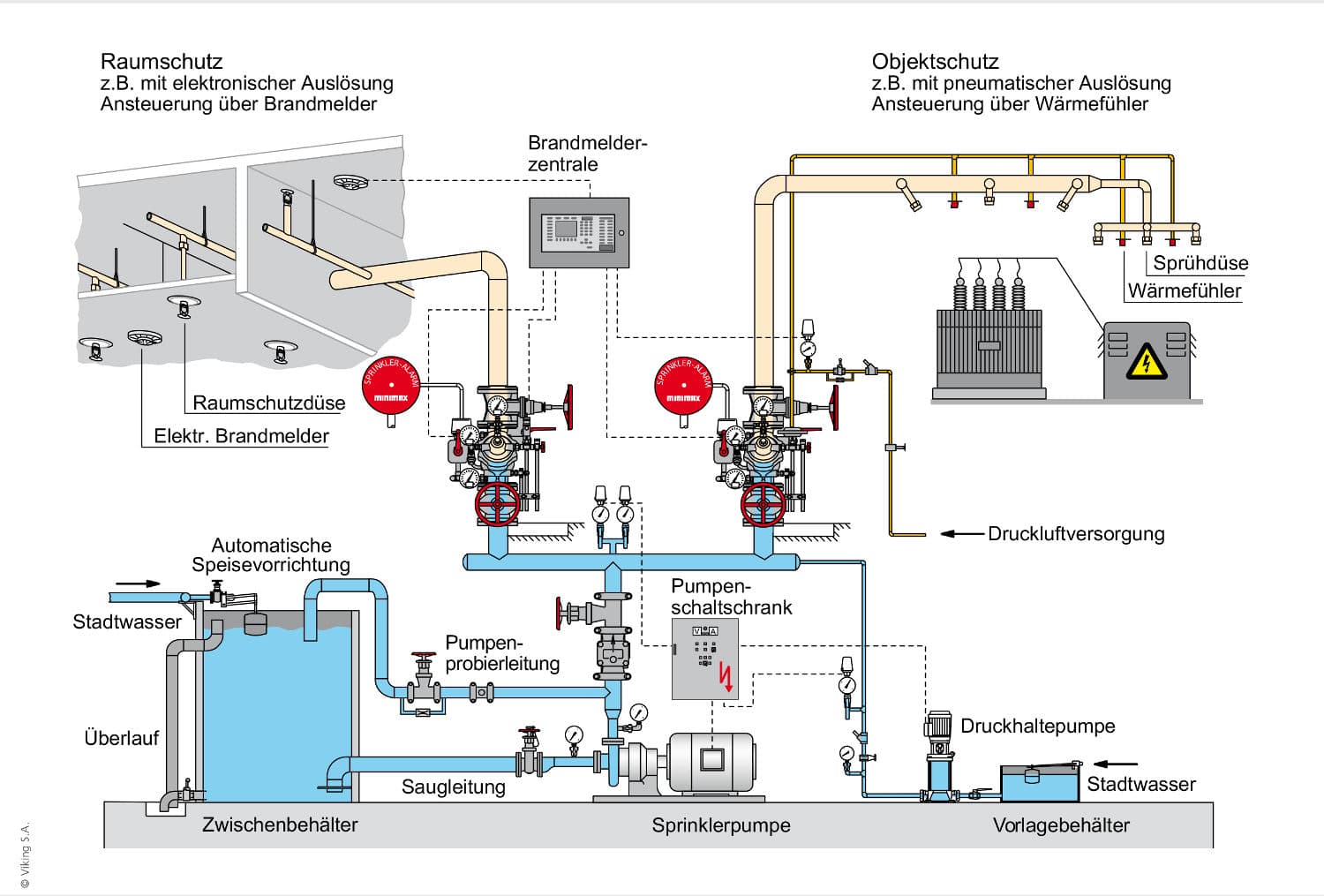

Water spray extinguishing systems are installed both for object protection and room protection. Whereas in the case of object protection systems the extinguishing nozzles are directed straight at the object to be protected, they are distributed evenly throughout the area to be protected when used in room protection systems. In this case, the area to be protected can be sub-divided into different extinguishing areas so that sequential extinguishing takes place.

Room Protection / Object Protection

The building sections or objects to be protected are equipped with a pipeline network with open extinguishing valves which are sub-divided into several extinguishing areas. In standby mode, the extinguishing water is supplied up to the sprinkler valve stations. Fires are detected using electric or pneumatic triggering elements matched to the risk and environment.

Water is supplied through a supply tank and powerful pump.

As soon as the fire detection system detects a fire in the area to be protected, the corresponding sprinkler valve station is actuated and opened. The extinguishing water is only sprayed via the nozzles in the extinguishing area, binds the combustion heat and cools the burning material.

The water spray extinguishing system is ready for use again immediately after fire-fighting.

The installation of water spray extinguishing systems protects your company against the existence-threatening consequences of a fire, particularly against a longer interruption in business.

offers the installation of spark extinguishing systems to protect conveyor lines and filters against dust explosions as well as the installation of gas extinguishing systems for object protection (e.g. for machining centres).

We will be happy to draw up an individual protection concept for you. With a well thought-out fire protection concept, you send out a message of reliability and safety to your customers.