Spark Extinguishing System

In pneumatic transport equipment and mechanical conveyor systems which transport combustible materials, flying sparks can often lead to fires or filter explosions. Flying sparks are generally caused by the machines used or material soiling. Production downtime, high property damage and hazards for human life and limb are the result. In order to exclude this risk, extraction systems must be monitored for flying sparks and protected by spark extinguishing systems. If spark extinguishing systems in compliance with the directives of the Verband der Sachversicherer (Association of Non-Life Insurers) (VdS 2106) are installed, non-life insurers will grant a discount of up to 15%.

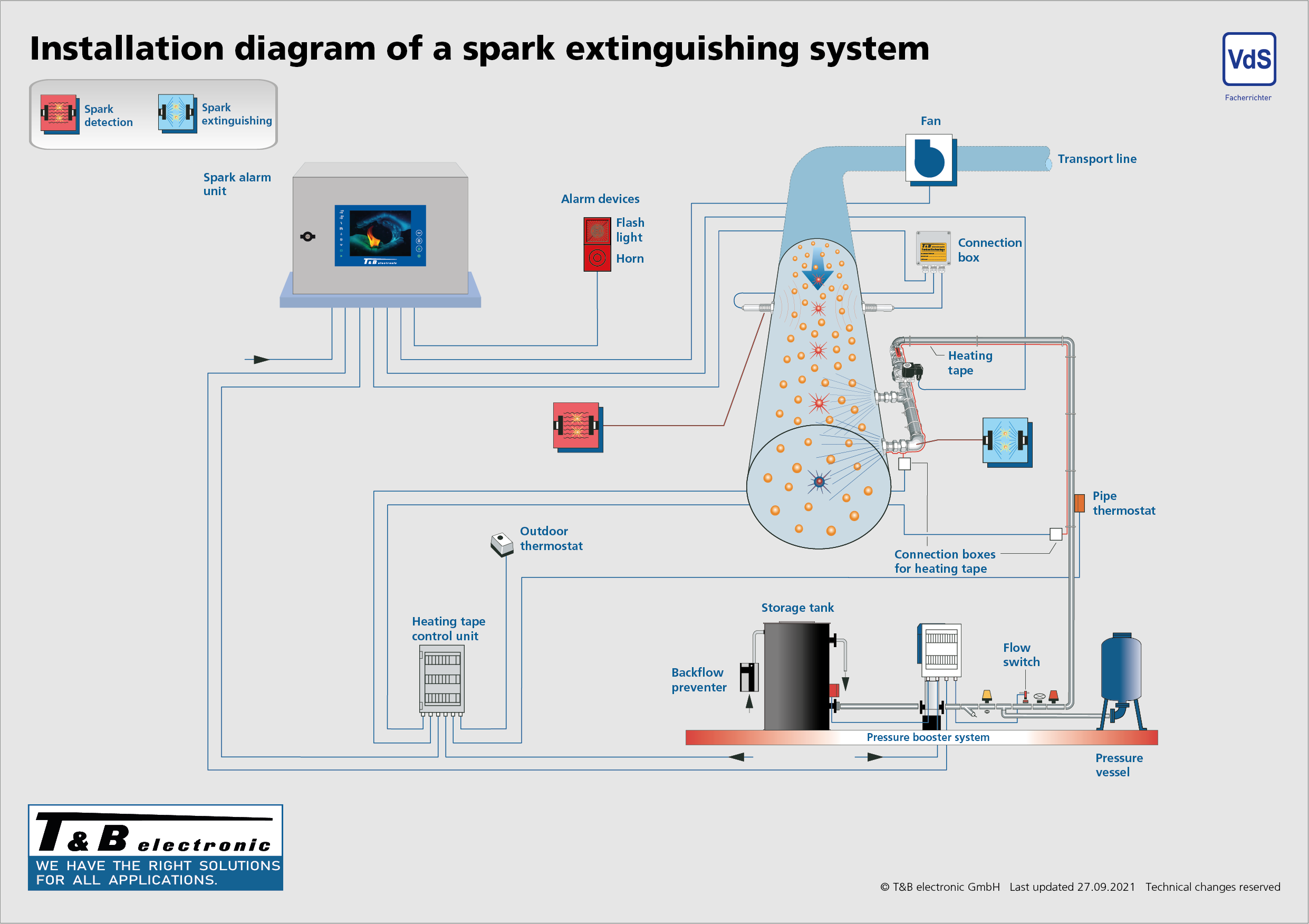

Function of the Spark Extinguishing System

In pneumatic conveyor lines, spark detectors and spark extinguishing systems should be installed downstream of the fan (since this may also generate sparks). The spark detectors detect minimal infrared rays and relay these to the spark alarm unit. From here, the extinguishing system is actuated within milliseconds and extinguishing water is injected into the extraction pipe via special nozzles. The flying sparks have to pass this extinguishing mist and are reliably extinguished in the process.

The minimum distance between a spark detector and the extinguishing equipment in an extraction system depends on the air velocity in the extraction line and the response time of the extinguishing system. The minimum distance in metres is calculated by multiplying the air velocity in m/s with a safety factor of up to 0.3 s (depending on the diameter of the delivery line). The safety factor designates the time between spark detection and build-up of the extinguishing mist. Within this period of time, an effective extinguishing water mist which will be able to reliably extinguish the flying sparks must be generated in the extraction line. Thus the following basically applies: the higher the air velocity, the greater the distance between spark detector and extinguishing system has to be to ensure that the extinguishing process always sets in before the spark arrives at the extinguishing spot.

All delivery lines to the filter and chip silo should be equipped with a spark detection and spark extinguishing system downstream of the fan. The spark detection system consists of at least two spark detectors monitoring the pipeline cross-section. The spark extinguishing system consists of a quick-opening solenoid valve and at least one extinguishing nozzle. The extinguishing nozzles are fitted with a cap to prevent soiling. The extinguishing process is continued until the last detected spark has passed the extinguishing section, then the automatic extinguishing system closes automatically. However, the spark extinguishing system remains in stand-by so that any new sparks can be dealt with immediately. The minimum extinguishing time is five seconds and is automatically extended if flying sparks persist. Individual sparks are reliably extinguished during the production process.

It is possible to effect a machine shut-down by means of an adjustable spark threshold of between 1 and 999 sparks within a given time unit. The number of sparks detected and the trigger threshold are visually displayed at the spark alarm unit. To be able to generate a perfect spray pattern, a flow pressure of at least 5 bar must be present at the automatic extinguishing system. If this is not the case, a pressure booster comprising a vertical centrifugal pump with diaphragm pressure tank and a storage tank are used. It is possible to connect the extinguishing water to an existing sprinkler system. Extinguishing systems that are located in areas threatened by frost must be equipped with an electric trace heating. The trace heating is controlled via an external thermostat with the associated heating strip monitoring system. All heated extinguishing water pipes and the extinguishing system itself must be insulated.

In the area around the valves and the extinguishing nozzles, it must be possible to detach the insulation for maintenance purposes. The spark detectors are equipped with built-in testing devices. The new generation of spark alarm units is equipped with an automatic detector test facility, so that manual alarm testing is no longer required in this case. An extinguishing water monitoring system constantly monitors whether extinguishing processes are running correctly and visually displays the extinguishing process at the spark alarm unit.

If a filter system works with an air return system, bypass smoke detectors are provided for installation in the return air ducts. These will immediately report any smouldering fires in the filter hoses and cause the fans to be switched off. Two differential temperature detectors are also installed in the filter system and immediately trigger at a temperature > 90°C. It is possible either to only trigger an alarm or actuate an extinguishing system. The spark alarm units are equipped with a microprocessor monitoring system. The fire alarm events and malfunctions are saved and displayed as plain text. Up to 2500 events can be stored.

Guideline for Spark Extinguishing Systems

The Verband der Sachversicherer applies the directive for spark extinguishing systems (VdS 2106). Among other things, this stipulates that a spark extinguishing system may only be installed by an installation company that has been approved by the VdS. Only approved components and devices may be used. For every spark extinguishing system, the approved installation company must prepare an installation test, a schematic drawing detailing function and fire break as well as a hydraulic calculation. The documents must be submitted to VdS during the acceptance procedure. Spark extinguishing systems must be checked and serviced by an approved installation company at regular intervals. Any faults determined must be eliminated without delay. Normally, maintenance intervals of six months are adequate. The company operating the spark extinguishing system must keep a logbook where malfunctions, technical inspections etc. are entered.