Spark Extinguishing Systems in the Textile Industry

Operating Mode of the Spark Extinguishing System

In production areas, pneumatic transport equipment and mechanical conveyor systems which transport combustible materials, flying sparks or hot spots can often lead to fires in the machines or silos or explosions in filters. These are generally caused by the machines used or by material soiling.

Production downtime, high property damage and hazards for human life and limb are the result. To exclude this risk, your production systems must be protected by spark extinguishing devices.

T&B works together with you to draw up customised protection concepts for your production system.

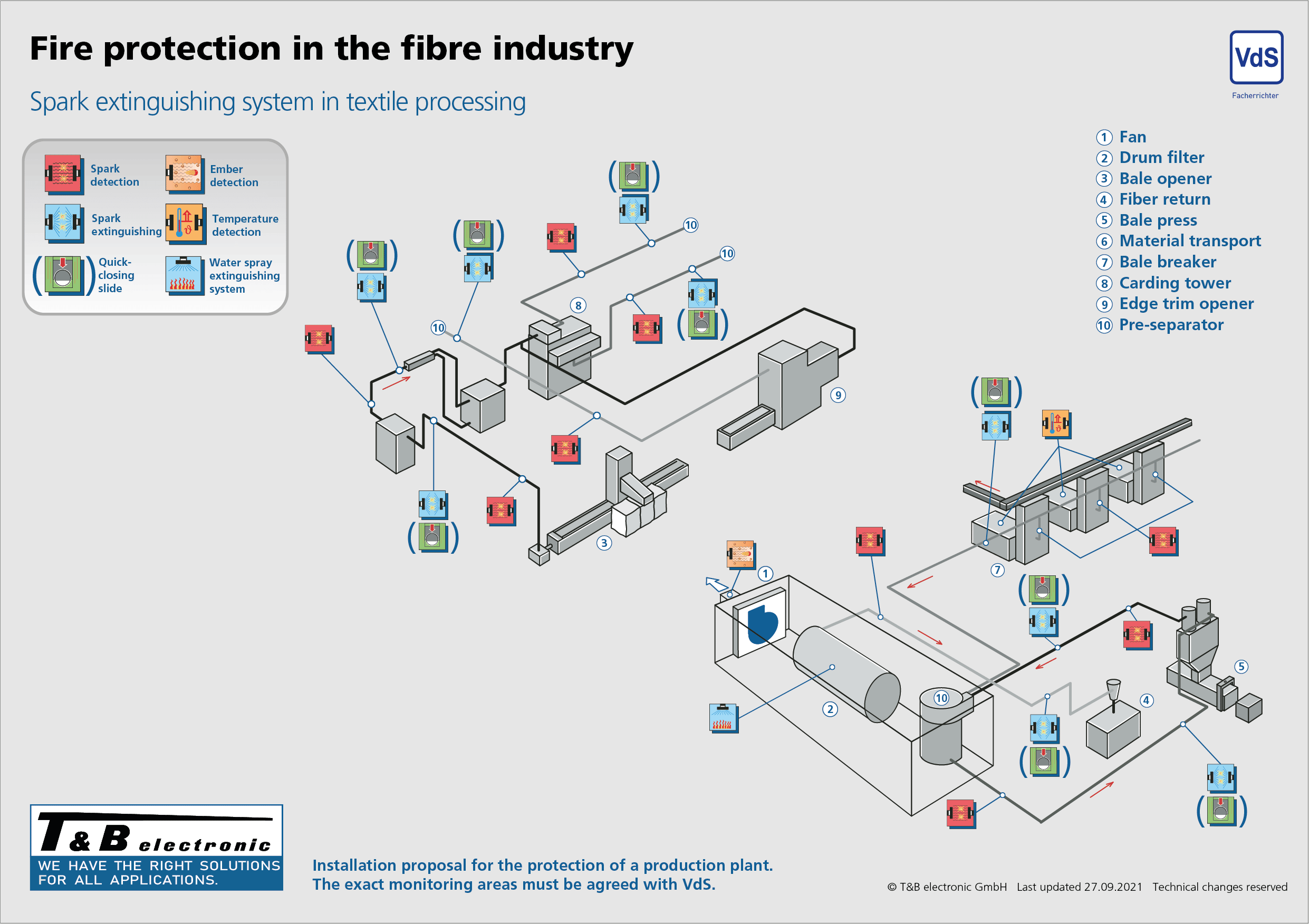

An example of protection for a production system is sketched below.